- Mobile Phone

- +86 13256067633

- rzzw@rizhaozhongwei.com

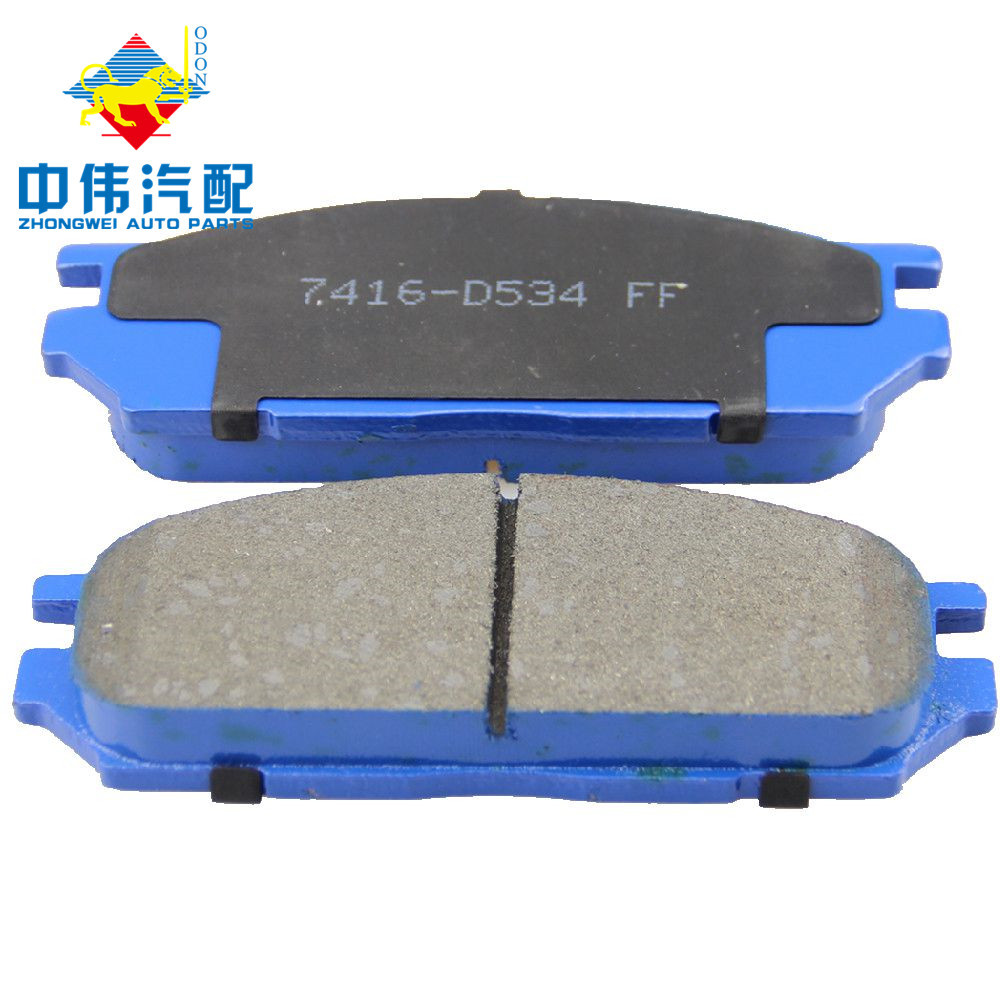

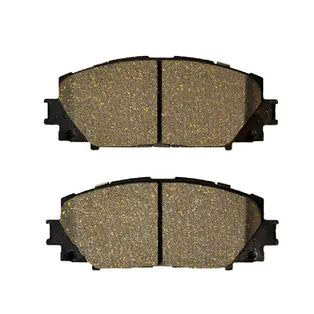

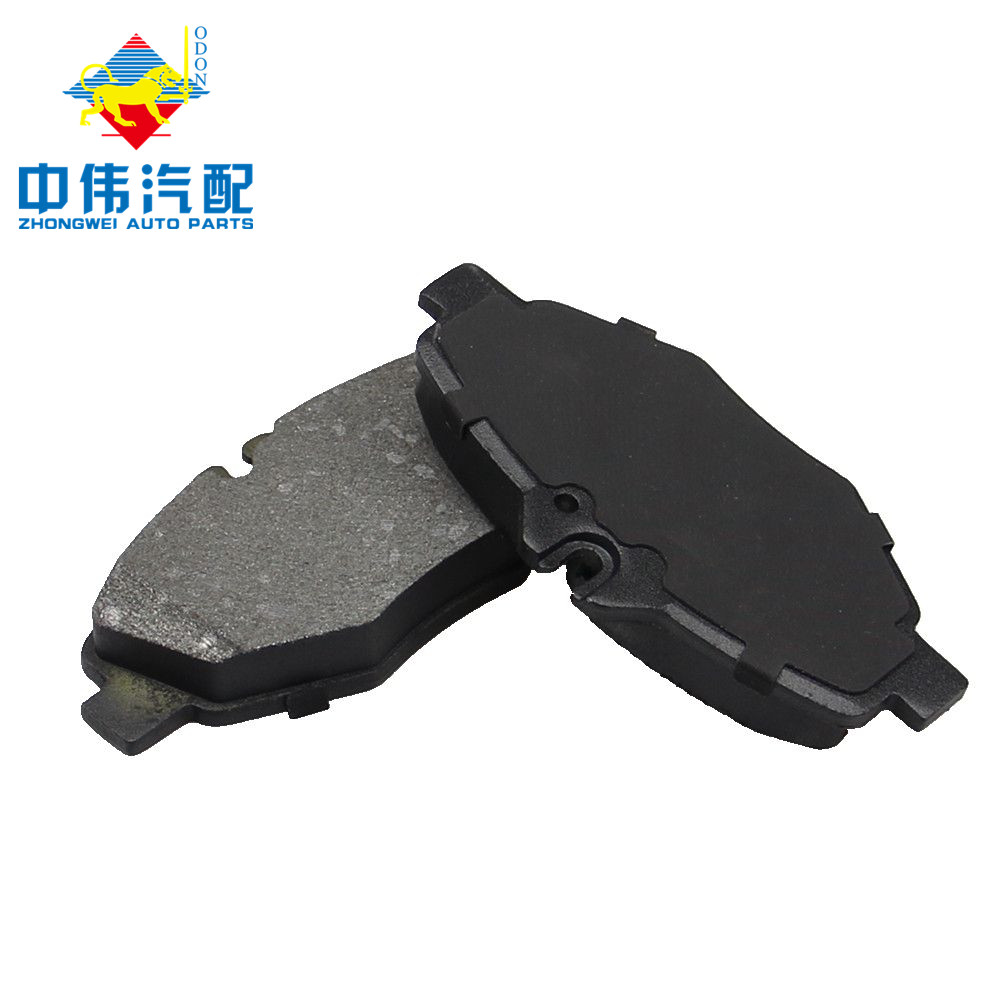

Types of Brake Pad: Wholesale Options from Leading Manufacturers

When it comes to choosing the right types of brake pad for your business, I'm here to help you find the perfect fit. Our selection of high-quality brake pads is ideal for wholesale buyers and manufacturers who demand reliability and performance. I understand that different vehicles and applications require specific braking solutions, and that's why my offerings include a variety of options, from semi-metallic to ceramic pads. I prioritize quality and durability, ensuring that our brake pads meet industry standards and deliver exceptional stopping power. With competitive pricing and the ability to meet large-volume orders, I aim to support your manufacturing needs effectively. By partnering with us, you’re not just getting brake pads; you’re getting a reliable source for your business. Let's talk about how we can meet your brake pad needs and keep your customers satisfied.

Types Of Brake Pad Ahead of the Curve Winning in 2025

As the automotive industry navigates towards a more sustainable future, the importance of selecting the right brake pads cannot be overstated. In 2025, businesses need to be ahead of the curve by understanding the various types of brake pads available in the market. Understanding the distinctions among organic, ceramic, and semi-metallic brake pads is crucial for procurement managers looking to enhance vehicle performance while minimizing environmental impact. Organic brake pads, known for their quiet operation and low dust production, are ideal for everyday driving scenarios. They provide excellent comfort but may wear out faster under high-performance conditions. Conversely, semi-metallic brake pads offer superior stopping power and are suited for heavy-duty applications, although they tend to generate more noise and dust. Ceramic brake pads strike a balance between performance and comfort, featuring durability and low dust emissions, making them increasingly popular for a wide range of vehicles. In the quest for innovation, the brake pad industry is witnessing advancements aimed at improving sustainability and performance. With new materials and manufacturing processes emerging, automotive businesses can leverage these innovations to fulfill global market demands. By staying informed about the latest developments in brake pad technology, procurement specialists can procure products that not only meet performance criteria but also align with environmental standards. As we move toward 2025, making informed decisions in brake pad selection will be vital for any company looking to secure a competitive edge in the market.

Types Of Brake Pad Ahead of the Curve Winning in 2025

| Brake Pad Type | Material | Performance Rating | Durability (Miles) | Noise Level |

|---|---|---|---|---|

| Ceramic | Ceramic composite | Excellent | 30,000 - 70,000 | Low |

| Semi-Metallic | Metallic fibers | Good | 20,000 - 60,000 | Moderate |

| Organic (Non-Asbestos) | Organic materials | Fair | 30,000 - 50,000 | High |

| Carbon-Composite | Carbon fiber | Excellent | 50,000 - 100,000 | Very Low |

Related Products