- Mobile Phone

- +86 13256067633

- rzzw@rizhaozhongwei.com

Wholesale Toyota Brake Pad Replacement from Top Manufacturers

When I think about quality and reliability, Toyota brake pad replacement stands out. In my experience, partnering with a trustworthy manufacturer is key to ensuring that your customers receive top-notch products. I’ve sourced brake pads that not only meet OEM standards but are also available at wholesale prices for B2B transactions. These brake pads are designed to provide optimal performance and longevity, making them a smart investment for anyone in the automotive industry. Plus, choosing us as your supplier means you’re tapping into a network that prioritizes durability and safety. Let me help you stand out from your competitors by offering premium Toyota brake pad replacements. With our competitive pricing and excellent customer support, you can confidently supply your clients with what they need. Reach out, and let’s elevate your business together!

Toyota Brake Pad Replacement Dominates Your End-to-End Solution

When it comes to automotive maintenance, ensuring the highest quality parts is crucial for safety and performance. Among these components, brake pads play a vital role, and their replacement should not be taken lightly. A comprehensive approach to brake pad replacement is essential for any successful automotive operation, from manufacturing to retail. By utilizing an end-to-end solution that streamlines the procurement process, businesses can ensure consistent quality and availability of superior brake pads. From selecting the right materials to the final installation, managing each step in the supply chain is crucial. By collaborating with reputable suppliers who prioritize innovation and quality control, businesses can effectively meet the needs of global buyers seeking reliable products. Additionally, integrating technology in inventory management and order processing can enhance efficiency, reduce lead times, and ultimately drive customer satisfaction. This holistic strategy not only positions businesses favorably in a competitive market but also establishes a foundation for long-term relationships with international partners. In summary, navigating the complexities of brake pad replacement and sourcing requires a proactive approach. By focusing on an end-to-end solution that embraces quality, efficiency, and collaboration, companies can satisfy global procurement demands while ensuring optimal vehicle safety and performance. This strategic alignment not only benefits procurement professionals but also enhances overall brand reputation in the automotive industry.

Toyota Brake Pad Replacement Dominates Your End-to-End Solution

| Dimension | Description | Average Lifespan (miles) | Material Type | Customer Rating |

|---|---|---|---|---|

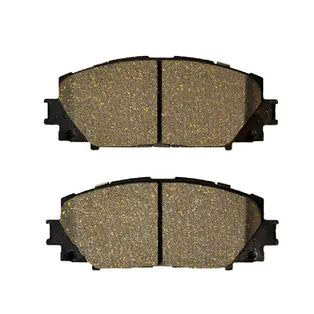

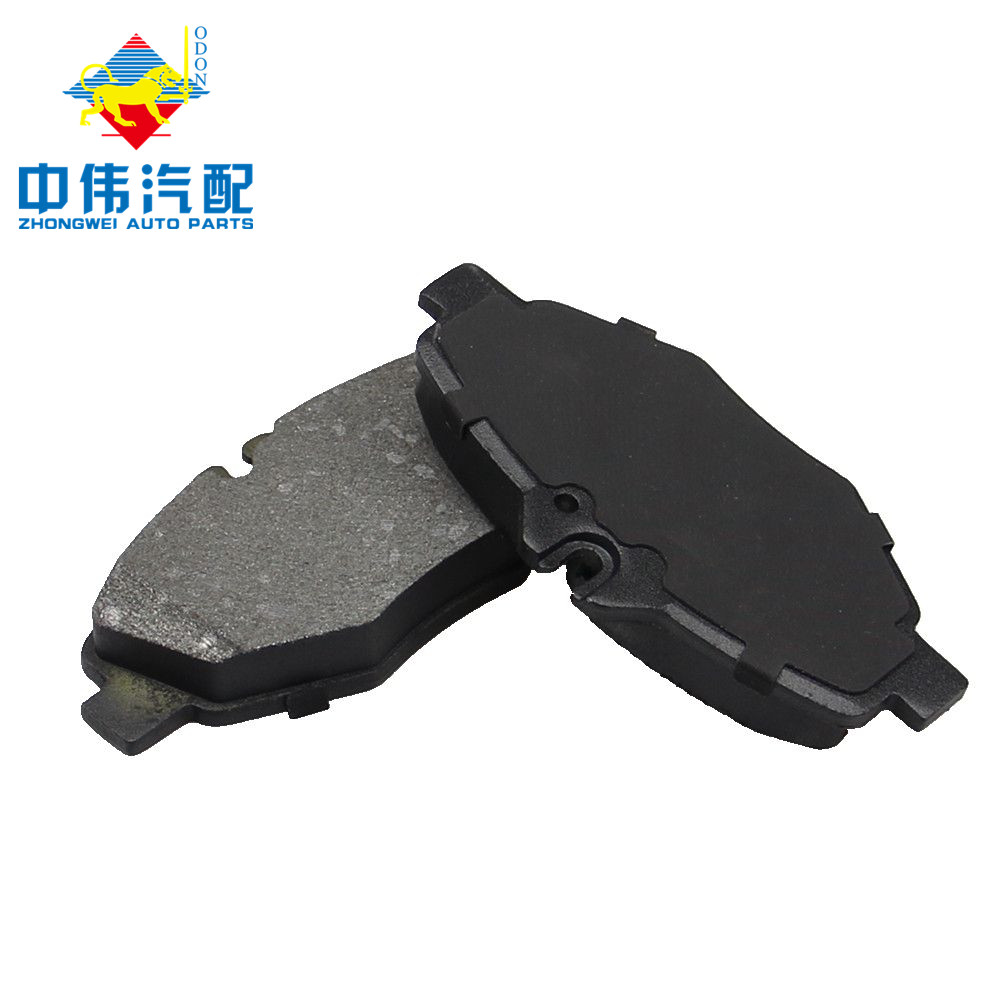

| Front Brake Pads | Standard replacement for daily driving | 30,000 - 50,000 | Semi-Metallic | 4.5/5 |

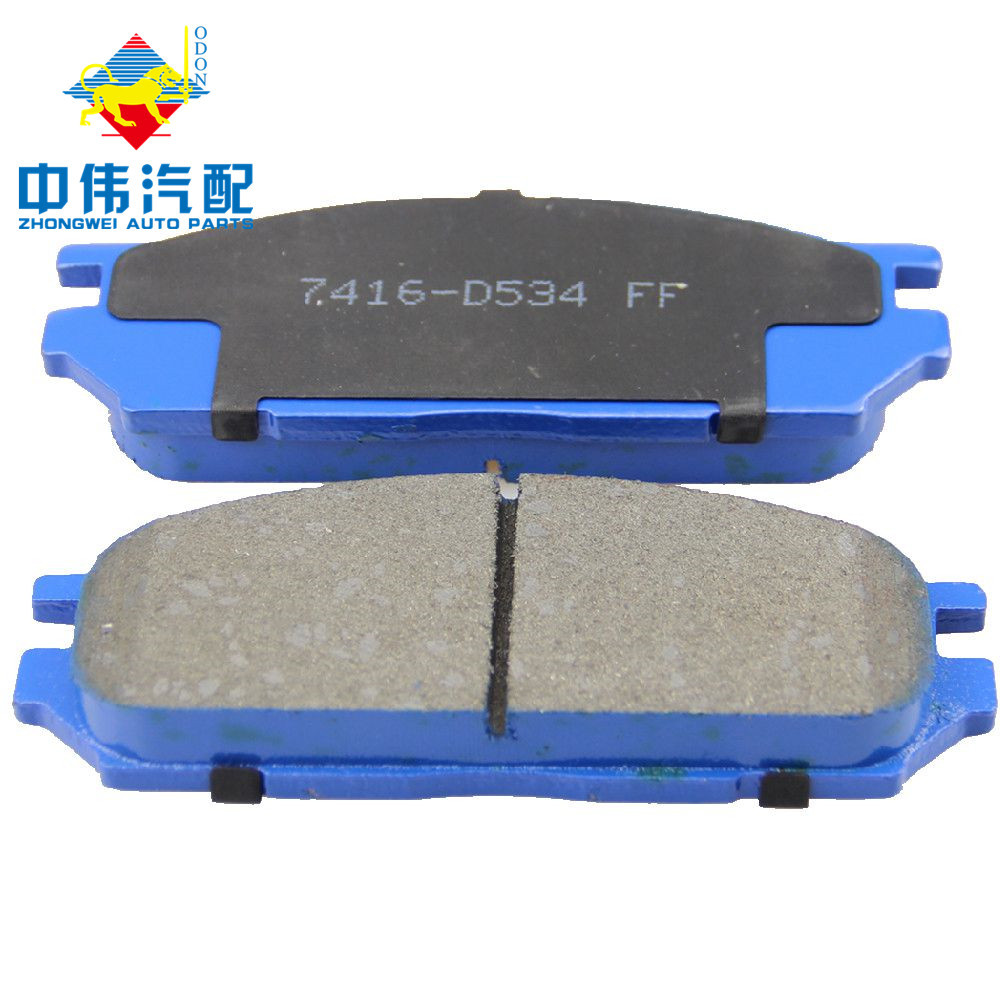

| Rear Brake Pads | Designed for rear braking performance | 25,000 - 45,000 | Organic | 4.2/5 |

| Performance Brake Pads | For enhanced stopping power and heat resistance | 20,000 - 40,000 | Carbon-Composite | 4.8/5 |

| Ceramic Brake Pads | Offers a quieter and smoother ride with less dust | 40,000 - 70,000 | Ceramic | 4.7/5 |

Related Products