- Mobile Phone

- +86 13256067633

- rzzw@rizhaozhongwei.com

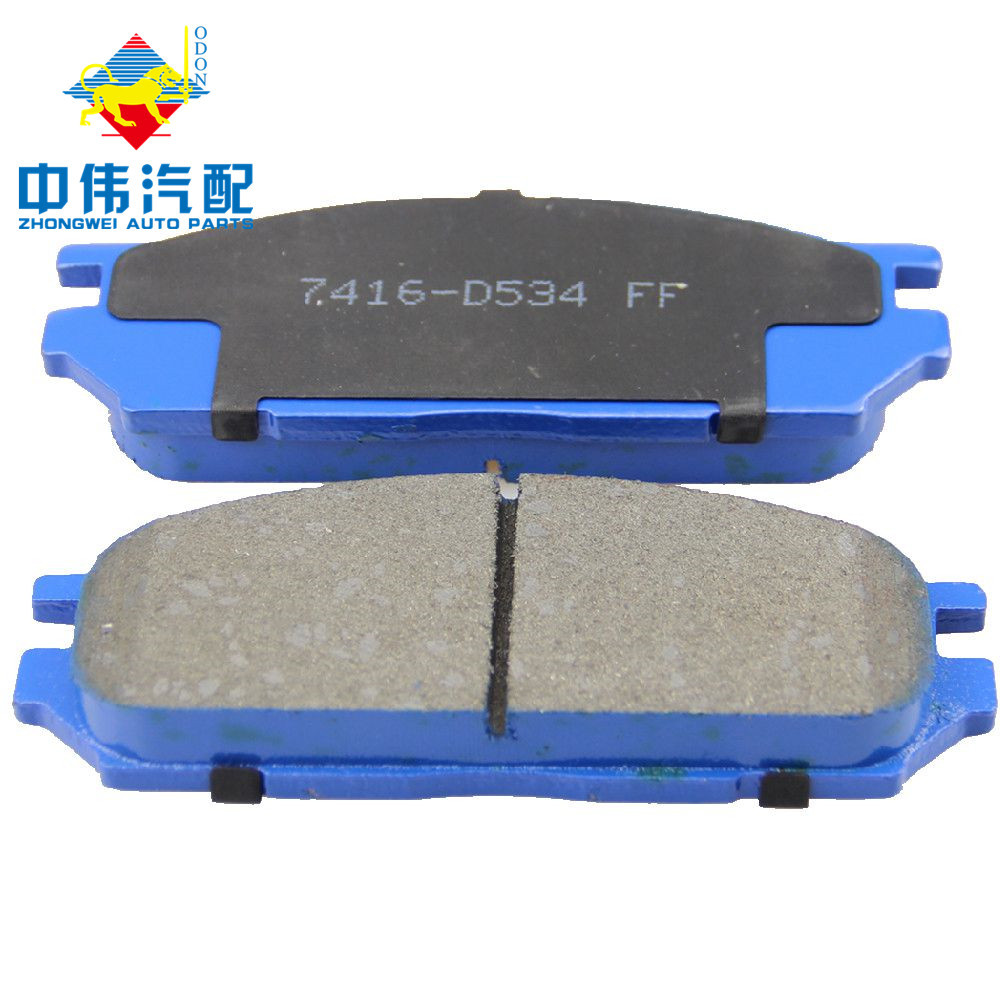

Semi Metallic Vs Ceramic Brake Pads: Wholesale Options from Manufacturers

When it comes to choosing the right brake pads for your vehicles, understanding the difference between semi-metallic and ceramic brake pads is crucial. As a trusted manufacturer in the automotive industry, we provide high-quality options suitable for various applications. I’ve found that semi-metallic brake pads offer superior performance in terms of stopping power, making them ideal for heavy-duty vehicles or aggressive driving conditions. On the other hand, ceramic brake pads are quieter and produce less dust, which is perfect for those seeking a smoother ride and less maintenance. Whether you're buying wholesale for a large fleet or needing quality brake pads for a specialty application, I’m here to help you find the best option for your needs. Our products are designed with durability in mind, ensuring you get the best value for your investment. Let us be your reliable partner in sourcing the right brake pads to meet your requirements!

Semi Metallic Vs Ceramic Brake Pads Ahead of the Curve Service Backed by Expertise

Choosing the right brake pads is crucial for optimal vehicle performance and safety, particularly in a world that demands reliability and durability from automotive components. Semi-metallic and ceramic brake pads are two popular options that each come with distinct advantages tailored to different driving conditions and preferences. Semi-metallic brake pads typically offer excellent stopping power and heat dissipation, making them well-suited for high-performance vehicles or heavy-duty applications. They contain metal fibers, which contribute to their enhanced performance but may lead to quicker wear on rotors. On the other hand, ceramic brake pads are known for their quieter operation and minimal dust production, appealing to drivers prioritizing cleanliness and comfort. These pads are made from a dense ceramic material, resulting in less wear on both the pads and rotors, thus providing a longer lifespan. While they may not perform as well under extreme conditions compared to semi-metallic options, they offer a balanced performance ideal for everyday driving. When choosing between these two types, it is essential to consider factors such as driving style, vehicle type, and specific environmental conditions. Leveraging expertise in automotive manufacturing, sourcing the right materials and ensuring superior quality in production is vital. Understanding the nuanced characteristics of both semi-metallic and ceramic brake pads allows for informed purchasing decisions, catering to diverse markets and consumer needs globally. Whether for performance vehicles or standard passenger cars, selecting the appropriate brake pad can significantly impact safety and efficiency on the road.

Semi Metallic Vs Ceramic Brake Pads

| Feature | Semi Metallic Brake Pads | Ceramic Brake Pads |

|---|---|---|

| Material Composition | Metallic fibers, copper, and other materials | Ceramic materials mixed with other substances |

| Noise Level | Generally noisier | Quieter operation |

| Dust Production | Higher dust production | Low dust production |

| Performance | Excellent stopping power, especially in high-performance scenarios | Stable performance across a wide range of conditions |

| Lifespan | Generally shorter lifespan due to wear | Longer lifespan, less wear |

| Cost | Usually lower initial cost | Higher initial cost, but better longevity |

Related Products