- Mobile Phone

- +86 13256067633

- rzzw@rizhaozhongwei.com

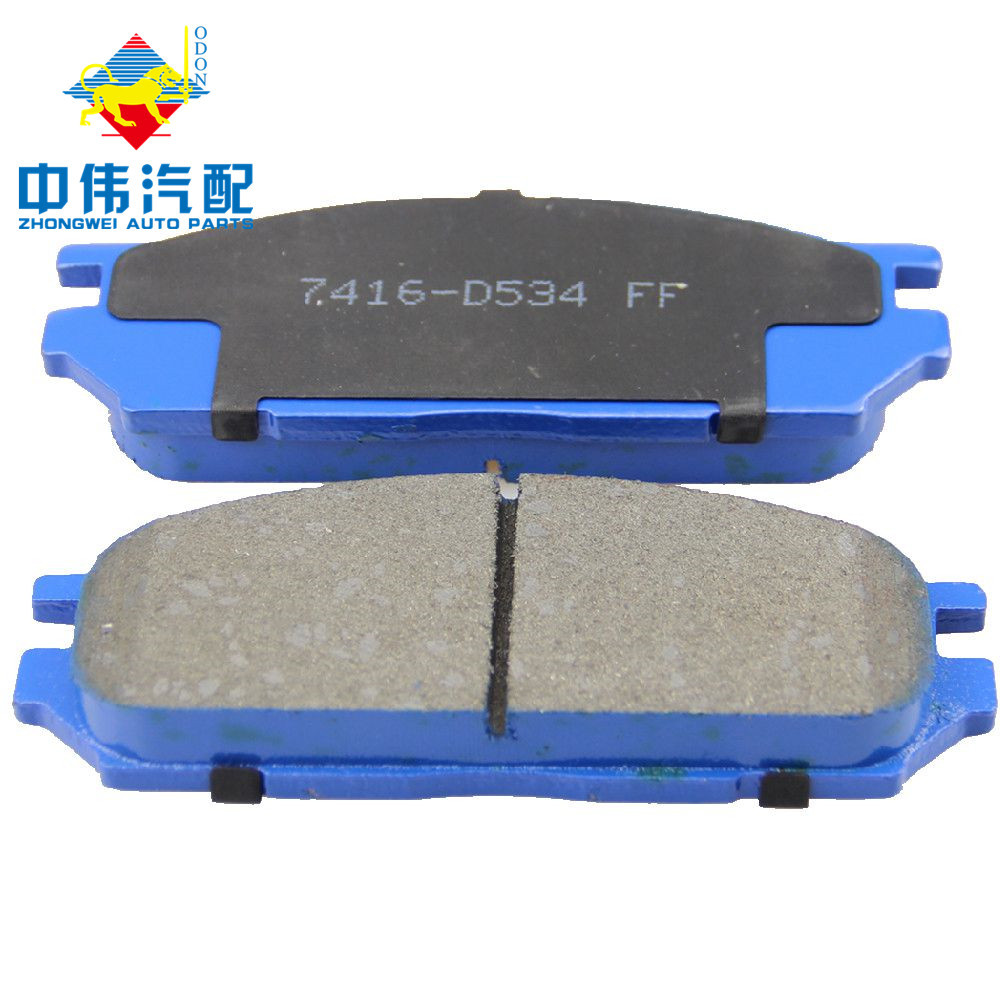

Ceramic Vs Metallic Brake Pads: Wholesale & Manufacturer Insights

When considering brake pads for your clients, it’s crucial to weigh the options between ceramic vs metallic brake pads. As a knowledgeable supplier in the field, I've seen firsthand the differences that can impact performance and customer satisfaction. Ceramic pads tend to be quieter and produce less dust, which some buyers prefer for daily drivers. On the other hand, metallic pads offer superior heat dissipation and are often the choice for high-performance vehicles. I can provide wholesale options from manufacturers who prioritize quality and reliability. Whether you're equipping a fleet or outfitting a shop, choosing the right brake pads can enhance vehicle safety and longevity. Allow me to assist you in finding the perfect balance between durability and cost-effectiveness that meets your purchasing needs. Partnering with a trusted manufacturer means you can count on consistent supply and top-notch products. Let’s connect to explore how I can support your brake pad sourcing today!

Ceramic Vs Metallic Brake Pads Winning in 2025 Manufacturers You Can Rely On

When it comes to automotive brake pads, the choice between ceramic and metallic materials can significantly impact vehicle performance, safety, and maintenance. With evolving technology and user preferences, 2025 is set to highlight the strengths and weaknesses of both types of brake pads. Ceramic brake pads are known for their quiet operation, low dust production, and longer lifespan, making them a popular choice for daily drivers and those who prioritize comfort and cleanliness. Their ability to dissipate heat also helps in reducing brake fade, ensuring reliable stopping power under various conditions. On the other hand, metallic brake pads, often favored by performance enthusiasts, offer superior stopping power and heat resistance. These pads excel in high-intensity driving scenarios, providing consistent performance even in extreme conditions. However, they can generate more noise and dust, which may require more frequent maintenance and cleaning. As we look ahead to 2025, manufacturers that specialize in high-quality brake pads will be essential for global buyers seeking products that meet specific vehicle requirements and performance standards. Manufacturers that combine innovation with reliability will set the standard in the automotive parts market. As a global procurement professional, partnering with reputable manufacturers ensures access to the latest braking technologies, compliant with international safety regulations, and tailored to market needs. Whether you prioritize the quiet efficiency of ceramic pads or the robust performance of metallic options, identifying trusted suppliers will be crucial for meeting the demands of an increasingly competitive automotive landscape in the years to come.

Ceramic Vs Metallic Brake Pads

| Brake Pad Type | Durability (miles) | Noise Level (dB) | Dust Production | Heat Resistance (°F) | Performance Rating |

|---|---|---|---|---|---|

| Ceramic | 30,000 - 70,000 | 60 - 70 | Low | 500 | Excellent |

| Metallic | 20,000 - 40,000 | 70 - 80 | High | 800 | Good |

Related Products