- Mobile Phone

- +86 13256067633

- rzzw@rizhaozhongwei.com

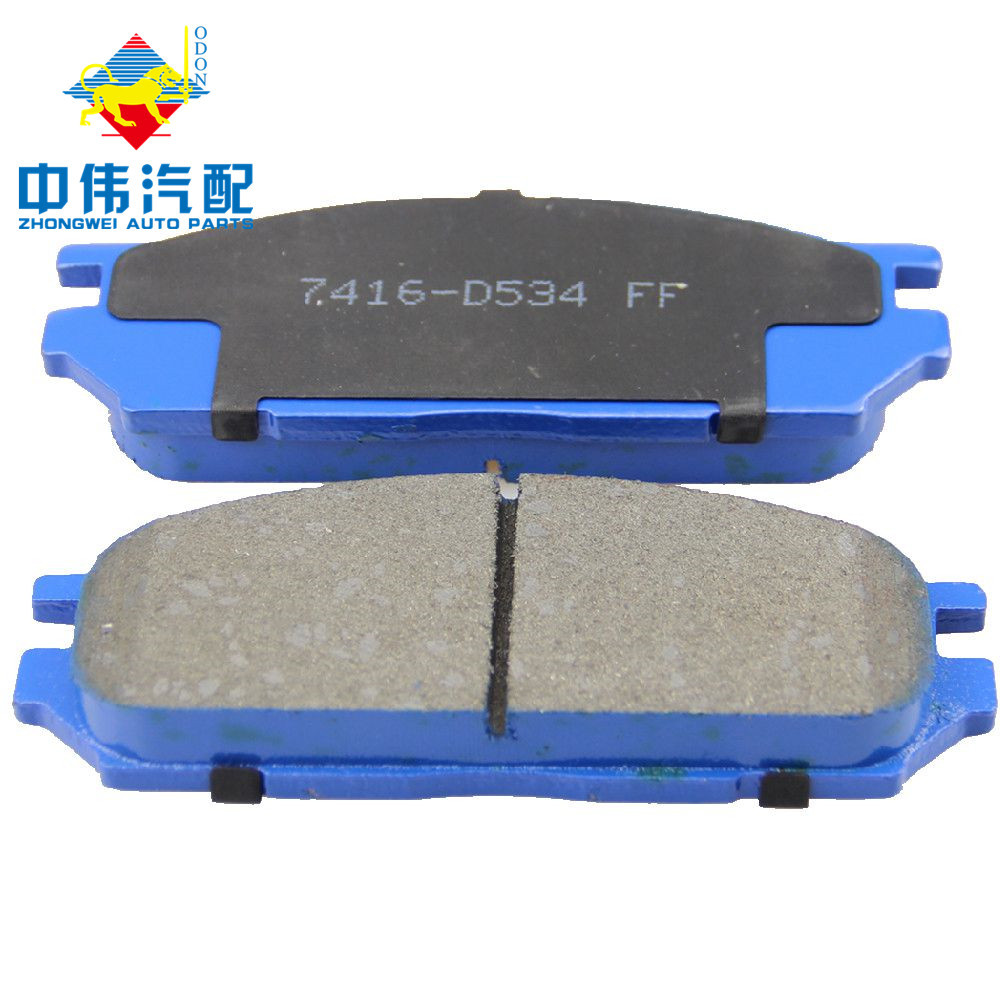

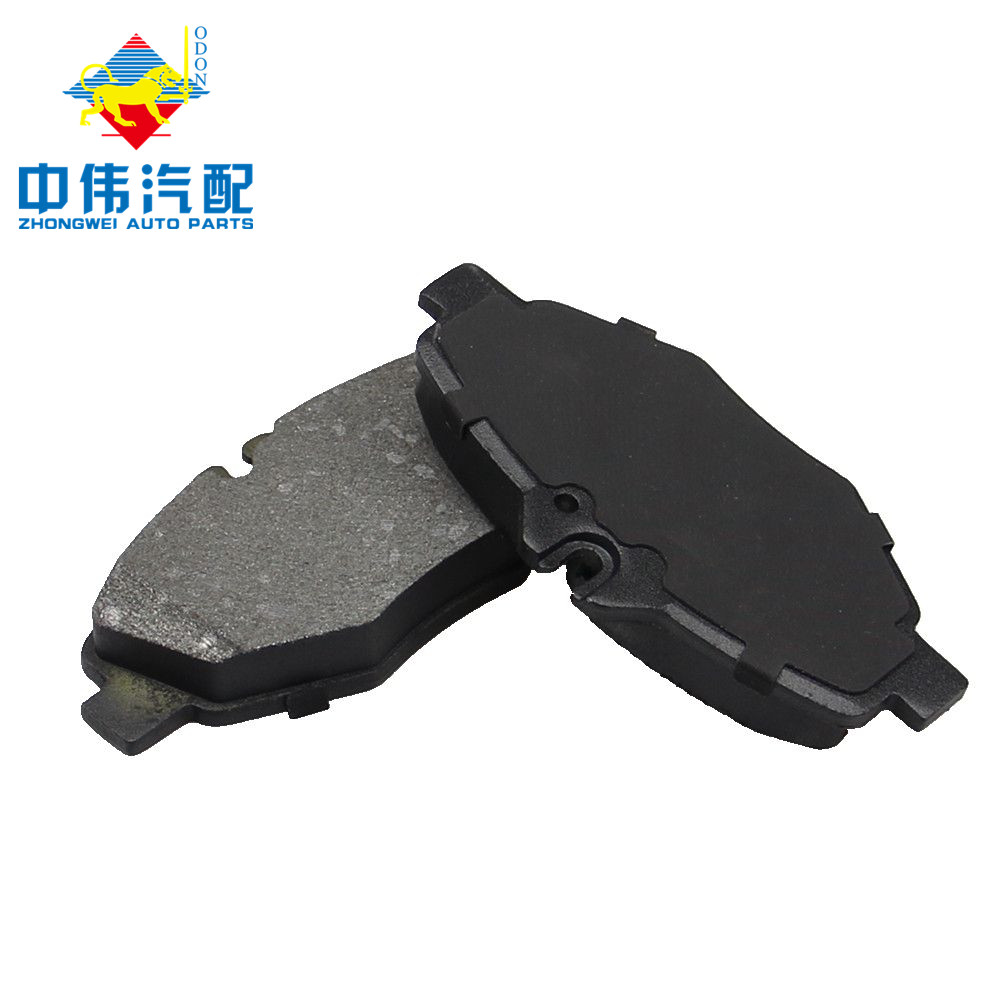

Ceramic V Semi Metallic Brake Pads Wholesale from Trusted Manufacturers

When I think about brake pads, I know quality matters, especially when choosing between Ceramic V Semi Metallic Brake Pads. As a wholesaler, I understand the importance of providing my clients with products that ensure safety and reliability. That's why these brake pads are ideal for both everyday driving and performance vehicles. Manufactured using advanced materials, these pads deliver exceptional stopping power while minimizing noise and dust. I appreciate how they offer the right balance between durability and performance, making them a fantastic choice for my customers. When I source these from a reputable manufacturer, I can trust that I’m supplying my clients with top-notch products that meet their needs. By choosing our Ceramic V Semi Metallic Brake Pads, you’re partnering with a supplier committed to quality and customer satisfaction. Let’s elevate your inventory and keep your customers safe on the road.

Ceramic V Semi Metallic Brake Pads Industry Giant Pioneers in the Field

In the automotive industry, the choice of brake pads plays a crucial role in ensuring vehicle safety, performance, and longevity. As the market shifts towards higher efficiency and lower emissions, the demand for advanced brake pad technologies has surged. Ceramic brake pads, known for their quieter operation and reduced dust production, are gaining popularity among consumers seeking a premium driving experience. On the other hand, semi-metallic brake pads, offering superior stopping power and reliability, remain a favorite for heavy-duty applications. Leading manufacturers in the brake pad industry are investing in research and development to enhance the performance characteristics of both ceramic and semi-metallic options. Innovations are being driven by the need for sustainable practices and superior quality, with a focus on environmentally friendly materials. These developments not only meet the increasing regulatory standards but also align with the growing consumer preference for eco-conscious products. As global purchasers navigate this landscape, understanding the strengths and applications of these brake pad types is essential. Collaborating with industry pioneers guarantees access to cutting-edge technology and reliable solutions, ensuring that procurement decisions meet both performance expectations and sustainability goals. Embracing these innovations positions businesses favorably in a competitive market, driving growth and customer satisfaction.

Ceramic V Semi Metallic Brake Pads Industry Giant Pioneers in the Field

| Brake Pad Type | Material Composition | Heat Resistance (°C) | Noise Level (dB) | Durability (miles) | Market Share (%) |

|---|---|---|---|---|---|

| Ceramic | Ceramic fibers, bonding agents | 500 | 65 | 30,000 | 40 |

| Semi Metallic | Metallic fillers, friction modifiers | 600 | 75 | 25,000 | 60 |

| Organic | Organic fibers and materials | 400 | 70 | 20,000 | 15 |

| Low Metals | Low metallic content with organic fibers | 450 | 68 | 28,000 | 20 |

Related Products