- Mobile Phone

- +86 13256067633

- rzzw@rizhaozhongwei.com

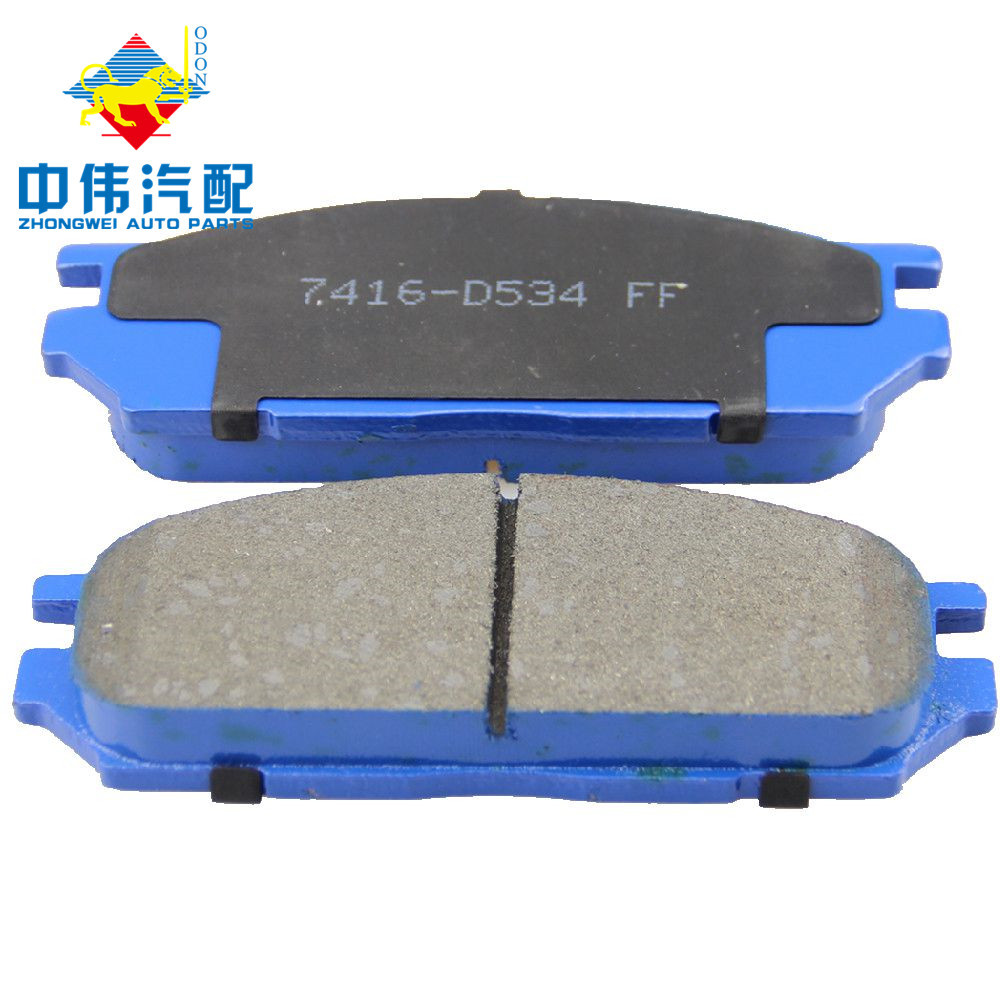

Wholesale Ceramic or Metallic Brake Pads from Trusted Manufacturers

When I think about the best braking systems, ceramic or metallic brake pads always come to mind. As a wholesale manufacturer, I understand the importance of quality and durability in automotive parts. Our brake pads are designed to meet the diverse needs of various vehicles, ensuring optimal performance and safety for every ride. I’ve seen firsthand how the right brake pads can enhance stopping power and reduce noise, making them ideal for both everyday drivers and heavy-duty applications. Whether you're looking to stock up for your auto shop or outfit a fleet, our products stand out for their reliability and value. With our commitment to excellence, you can trust that our ceramic or metallic brake pads will keep your clients satisfied and coming back for more. Join us in delivering the best to your customers—let's drive forward together!

Ceramic Or Metallic Brake Pads For the Current Year Pioneers in the Field

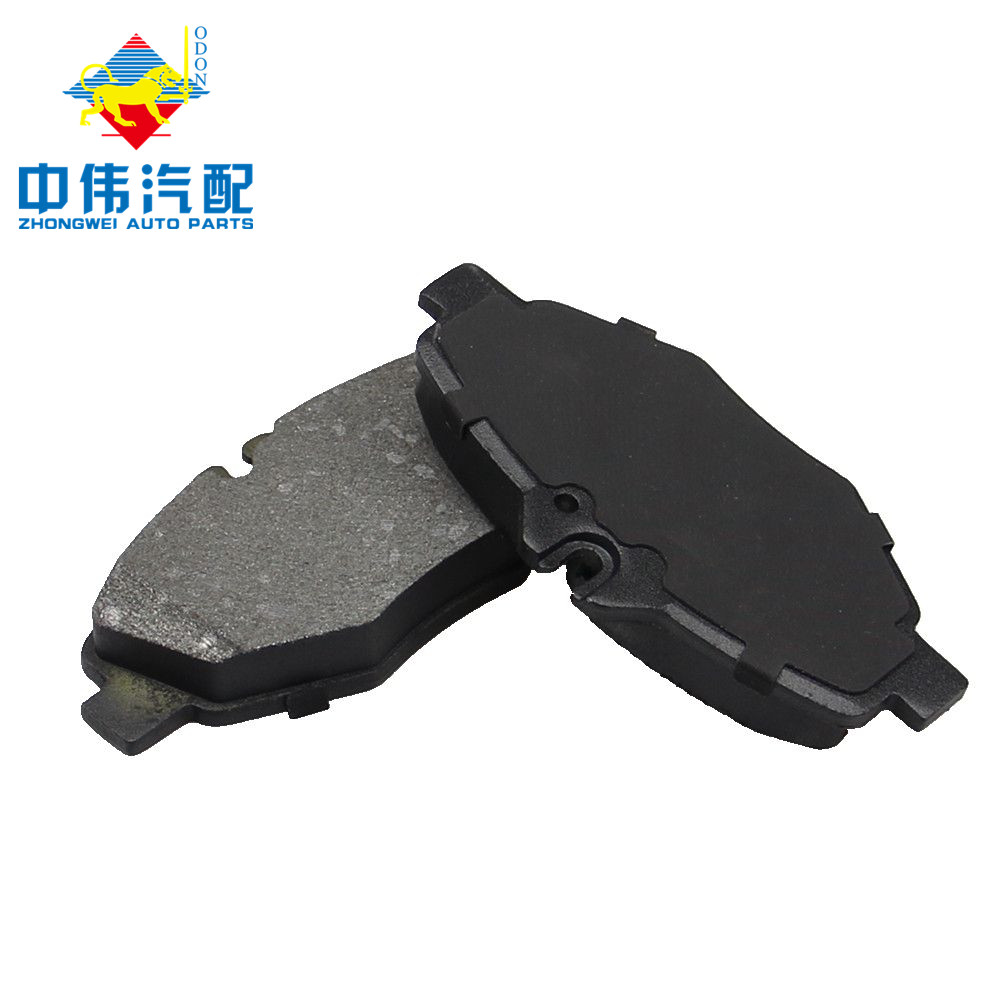

Choosing the right brake pads is crucial for both safety and performance in automotive applications. As we progress into the current year, a key consideration for procurement teams worldwide is whether to opt for ceramic or metallic brake pads. Each type offers distinct advantages that cater to different driving conditions and user preferences. Ceramic brake pads are known for their quieter operation and reduced dust production, making them an ideal choice for passenger vehicles focused on comfort and cleanliness. Their thermal stability ensures consistent braking performance over a range of temperatures. On the other hand, metallic brake pads, which contain a higher percentage of metal fibers, provide superior stopping power and durability under extreme conditions, making them well-suited for heavy-duty vehicles or high-performance applications. When sourcing brake pads, it’s essential for global buyers to consider the specific needs of their target market, including the type of vehicles prevalent in their region, driving conditions, and consumer preferences. Staying informed about the latest innovations in brake pad technology can help ensure that procurement decisions align with market demands, ultimately enhancing both customer satisfaction and safety.

Ceramic Or Metallic Brake Pads For the Current Year Pioneers in the Field

| Type | Advantages | Disadvantages | Ideal Use |

|---|---|---|---|

| Ceramic | Quiet performance, low dust, less wear on rotors. | Higher cost, may fade under heavy braking. | Daily driving, light trucks, and sedans. |

| Metallic | Strong stopping power, good heat dissipation. | Noisy, more brake dust, can wear rotors faster. | Heavy-duty applications, performance cars. |

| Organic | Soft on rotors, quiet operation. | Shorter lifespan, prone to fade under high temperatures. | Light vehicles, city driving. |

Related Products