- Mobile Phone

- +86 13256067633

- rzzw@rizhaozhongwei.com

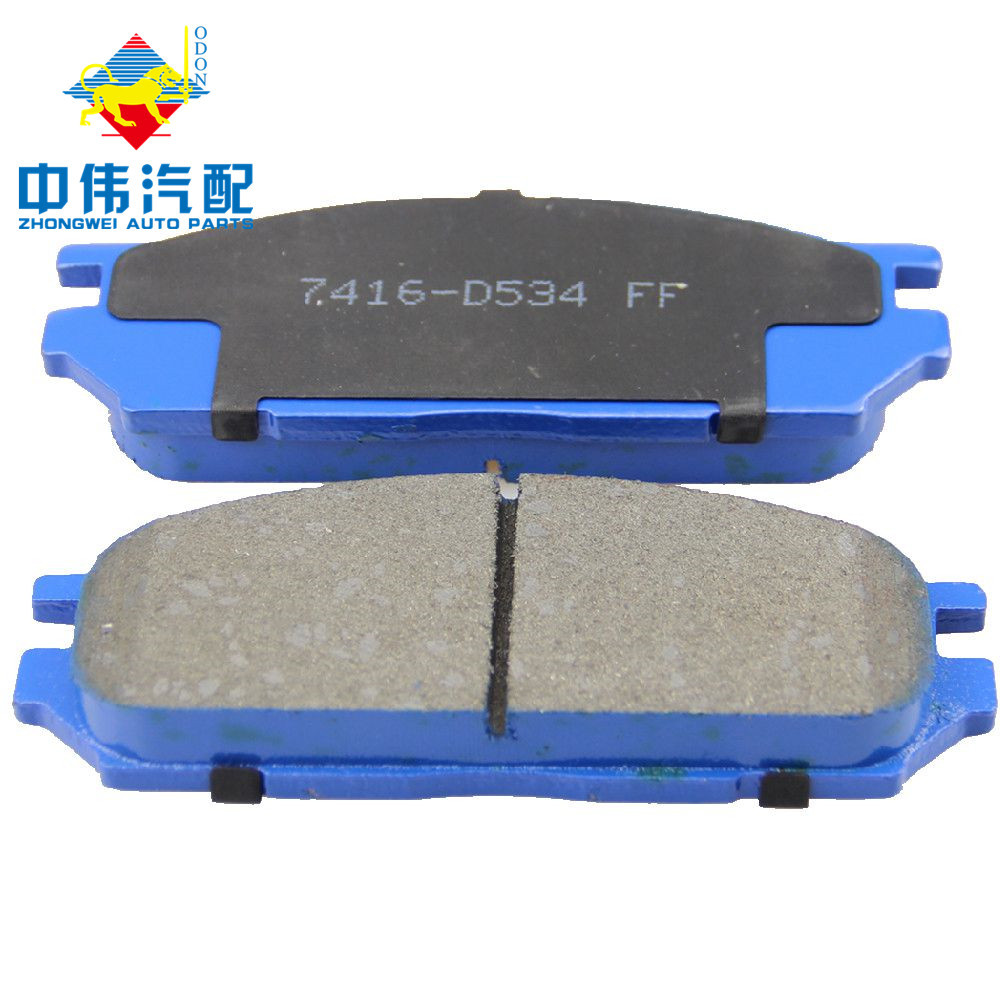

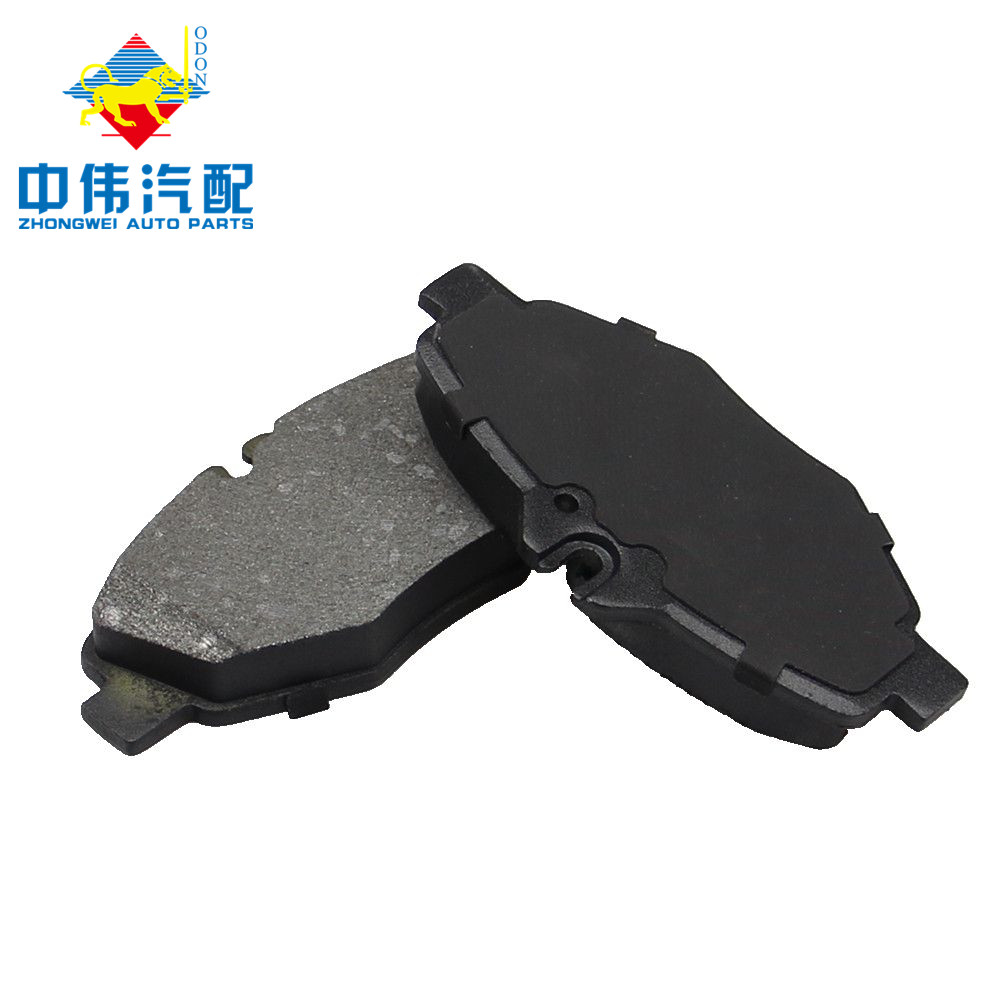

Wholesale Ceramic Brake Pad Manufacturer - Quality and Performance

When I think about high-quality brake components, ceramic brake pads always come to mind. Perfect for both everyday driving and demanding performance, these pads offer the ideal balance of durability and noise reduction. As a manufacturer, I understand the importance of reliability in your business. That’s why I’ve ensured our ceramic brake pads are rigorously tested for consistent performance and safety. Buying in wholesale means you not only save money but also stock up on a product that your customers will trust. These brake pads provide excellent stopping power while being gentle on rotors, reducing wear and tear. Whether you’re looking to enhance your product line or meet your clients' needs, our ceramic brake pads stand out in the market. Let’s work together to provide your customers with the best in automotive safety and efficiency. Get in touch to discuss wholesale pricing and availability today!

Ceramic Brake Pad Where Service Meets Innovation From Concept to Delivery

In the ever-evolving automotive industry, the demand for high-performance components is paramount. Ceramic brake pads exemplify this blend of innovation and quality, providing superior stopping power while minimizing noise and dust emissions. At the intersection of service and cutting-edge technology, manufacturers are crafting products that not only meet safety standards but also enhance the overall driving experience. From the initial concept to the final delivery, the journey of developing ceramic brake pads involves rigorous design, testing, and quality assurance processes. Engineers harness advanced materials and innovative manufacturing techniques to create brake pads that withstand extreme conditions while ensuring maximum durability. This commitment to innovation allows producers to offer a diverse range of products tailored to the specific needs of various vehicle types, ensuring global buyers have access to top-tier solutions. For procurement professionals, partnering with manufacturers committed to innovation and quality means accessing a reliable supply chain that supports both immediate needs and future advancements in automotive technology. As the industry continues to prioritize sustainability and performance, the selection of high-quality ceramic brake pads will play a crucial role in driving market success and enhancing vehicle safety across global markets.

Ceramic Brake Pad: Where Service Meets Innovation From Concept to Delivery

| Material Type | Friction Rating | Noise Level (dB) | Heat Resistance (°C) | Warranty (Years) |

|---|---|---|---|---|

| Ceramic | A | 65 | 600 | 3 |

| Semimetallic | B | 70 | 700 | 2 |

| Organic | C | 72 | 500 | 1 |

| Low-Metallic | A | 68 | 650 | 2 |

Related Products