- Mobile Phone

- +86 13256067633

- rzzw@rizhaozhongwei.com

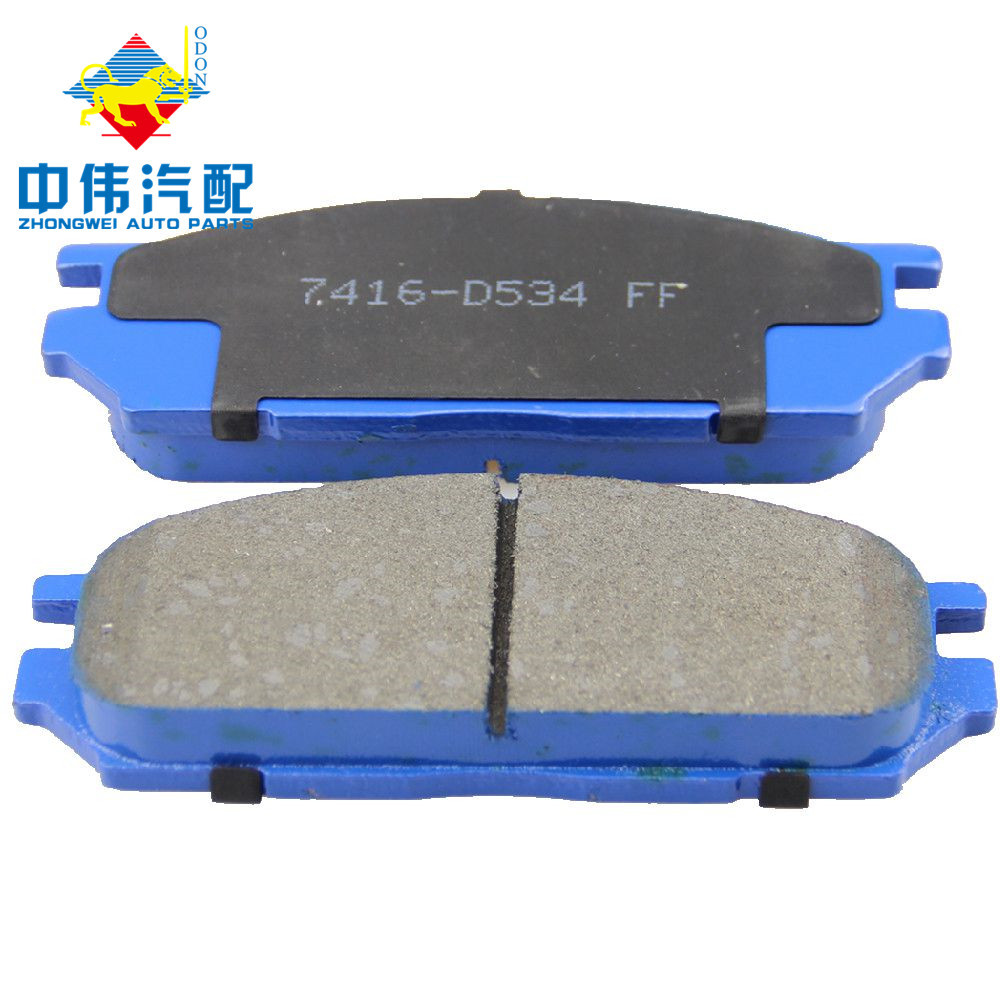

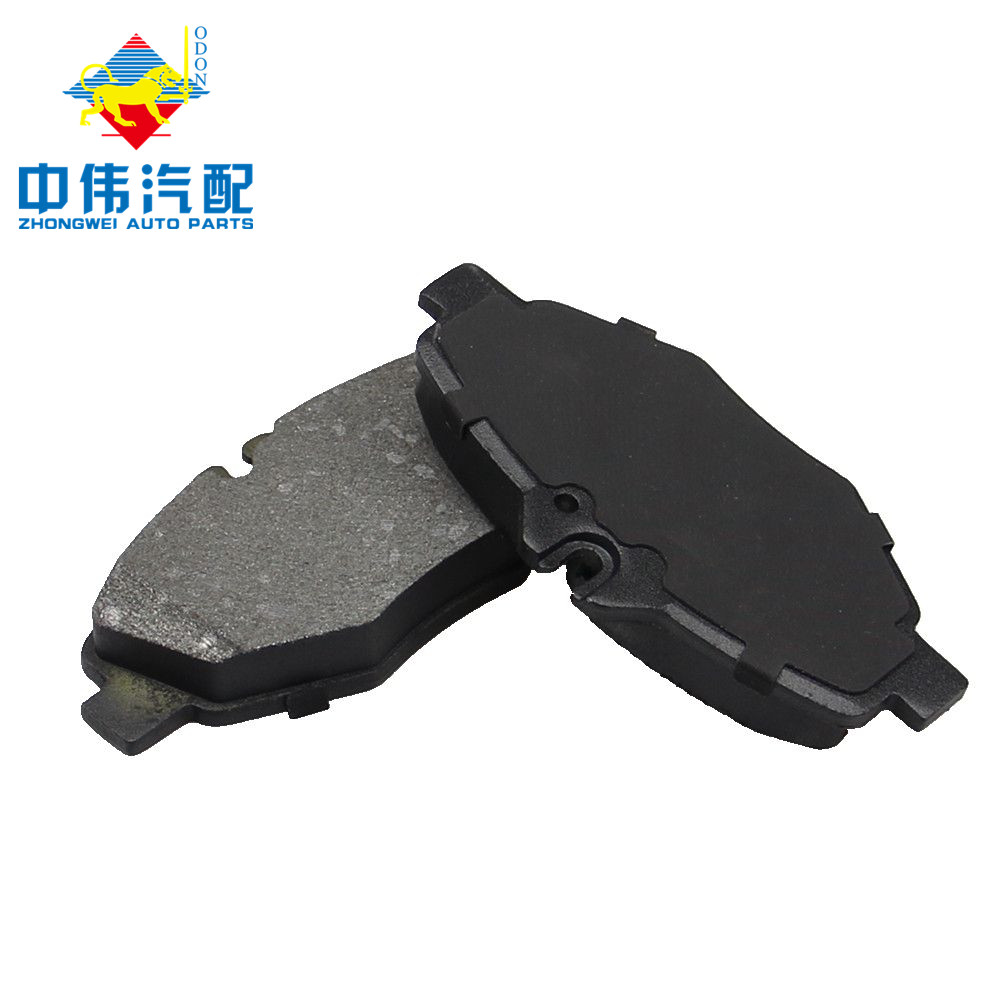

Wholesale Brake Pad Shims from Leading Manufacturer for Optimal Performance

When it comes to sourcing high-quality brake pad shims, I understand the importance of durability and reliability for your business. As a manufacturer, I take pride in offering wholesale options that cater specifically to your needs. Our brake pad shims are designed to reduce noise and vibration, providing optimal performance for a variety of vehicle models. We ensure that each shim is crafted from premium materials, guaranteeing long-lasting use. Whether you're a garage owner or a parts distributor, our easy-to-integrate products can help boost your sales and customer satisfaction. I focus on delivering consistent quality with every order, so you can trust that our brake pad shims will meet your expectations. Partner with us for competitive pricing and exceptional customer support. Let's make sure your clients get the best in safety and performance with our reliable brake pad shims. Reach out to me for wholesale inquiries, and let's elevate your inventory!

Brake Pad Shims Manufacturer Ahead of the Curve

When it comes to enhancing vehicle safety and performance, brake pad shims are an essential component that is often overlooked. As the automotive industry evolves, the demand for high-quality brake pad shims is on the rise. Manufacturers that stay ahead of the curve by innovating in design, materials, and manufacturing processes are becoming increasingly valuable partners for global buyers seeking reliability and performance. Incorporating advanced materials and state-of-the-art production techniques allows for the development of brake pad shims that not only improve braking efficiency but also reduce noise and vibration. By understanding the specific needs of varying market segments, manufacturers can tailor their products to meet different regional and application-specific requirements. This customization capability can lead to improved performance and customer satisfaction, making such manufacturers ideal sourcing partners. As environmental standards become stricter, the focus on sustainable and eco-friendly practices in production is more critical than ever. Companies that prioritize green manufacturing processes not only contribute to a healthier planet but also appeal to a growing segment of environmentally-conscious consumers. By choosing a forward-thinking manufacturer of brake pad shims, global buyers can ensure they are investing in quality products that reflect both innovation and sustainability.

Brake Pad Shims Manufacturer Ahead of the Curve

| Material Type | Thickness (mm) | Friction Coefficient | Temperature Resistance (°C) | Sound Dampening Rating |

|---|---|---|---|---|

| Rubber | 2.0 | 0.35 | 150 | High |

| Metallic | 1.5 | 0.45 | 200 | Medium |

| Ceramic | 1.8 | 0.30 | 250 | Very High |

| Composite | 2.5 | 0.38 | 180 | High |

Related Products