- Mobile Phone

- +86 13256067633

- rzzw@rizhaozhongwei.com

Best Brake Pad Material: Wholesale Options from Top Manufacturers

When it comes to brake pad materials, I know the importance of choosing the best for your customers. Our top-of-the-line options are crafted using advanced technology to ensure superior performance and longevity. As a leading manufacturer, we offer wholesale pricing that makes it easy to stock your inventory without breaking the bank. Whether you’re serving high-performance vehicles or everyday commuters, our brake pads provide reliable stopping power and reduced noise, ensuring driver satisfaction. I’m here to help you find the best brake pad material that fits your needs. With a range of formulations designed to meet various driving conditions, you can trust that our products will enhance the safety and comfort of your clientele. Let’s elevate your offerings together with reliable brake pads that keep everyone on the road safe. Reach out today to learn more about how we can partner for your success!

Best Brake Pad Material Now Trending Supplies the World\u2019s Top Brands

In the ever-evolving automotive industry, the demand for high-quality brake pads has never been more crucial. With an increasing focus on safety, performance, and sustainability, the best brake pad materials currently trending not only enhance vehicle performance but also meet the rigorous standards set by leading automotive brands. Advanced materials such as ceramic, semi-metallic, and organic compounds are paving the way for enhanced braking efficiency, reduced noise, and lower dust emissions. Global buyers are keen on sourcing brake pads that align with these innovations. Factors such as durability, heat resistance, and friction performance are paramount for selecting the right supply chain partner. As automakers strive to implement cutting-edge technology in their vehicles, the demand for premium brake pad materials will continue to rise. Procurement teams should seek partnerships with manufacturers who are not only aware of the latest trends but also committed to sustainable practices that minimize environmental impact. As the market evolves, staying ahead of trends in materials and manufacturing processes can be a decisive factor in maintaining a competitive edge. Collaborating with leading suppliers that prioritize quality and innovation will ensure access to the best brake pad materials, aligning with the expectations of discerning automotive brands worldwide. Buyers should prioritize suppliers who can demonstrate a proven track record in quality assurance and cutting-edge development to meet the complex demands of the modern automotive landscape.

Best Brake Pad Material Now Trending Supplies the World’s Top Brands

| Material Type | Friction Coefficient | Durability (Miles) | Heat Resistance (°C) | Eco-Friendliness Rating |

|---|---|---|---|---|

| Semi-Metallic | 0.35 - 0.45 | 30,000 | 400 | Moderate |

| Organic | 0.30 - 0.40 | 20,000 | 250 | High |

| Ceramic | 0.32 - 0.37 | 40,000 | 300 | Very High |

| Low-Metallic | 0.34 - 0.46 | 35,000 | 350 | Moderate |

| Sintered | 0.38 - 0.50 | 45,000 | 500 | Low |

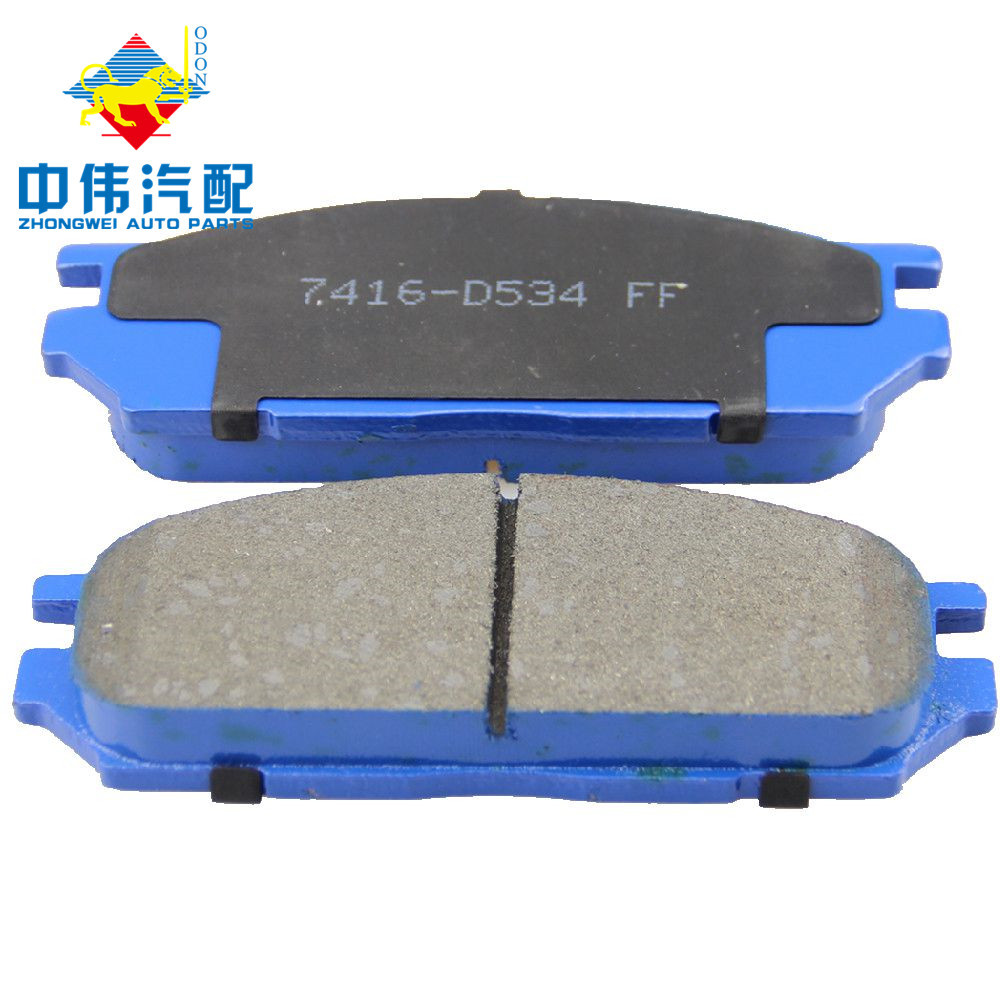

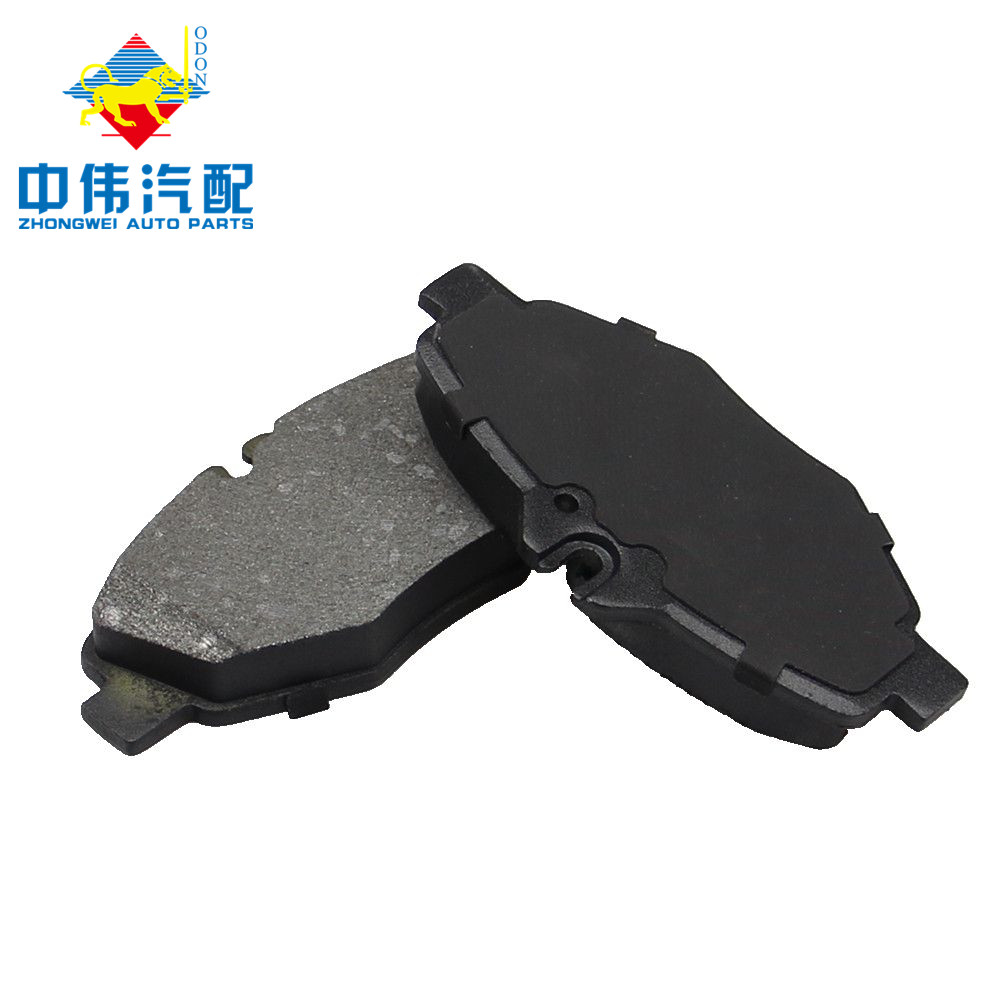

Related Products